- TOP

- Company Profile

OHASHI ENGINEERING CO., LTD. was founded in Tokyo more than half a century ago.

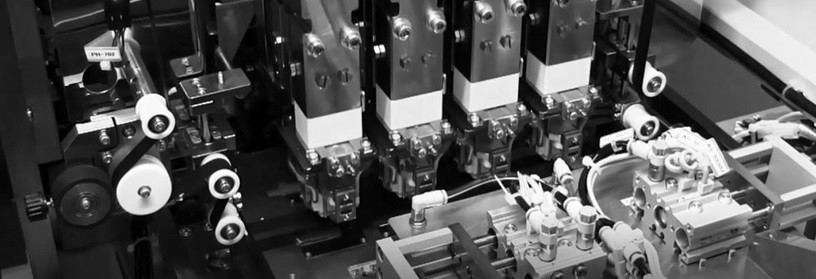

OHASHI ENGINEERING CO., LTD. was founded in Tokyo more than half a century ago.We are a quite unique maker to continue our basic business of precision sheet metal, and to develop, manufacture and sell the micro electronics equipment for ACF connection process multiply.

We developed high quality and better productive equipments based on our experience and knowledge of sheet metal business.

We always sought diversification of business and independence of management.

In sheet metal working, we not only manufacture by contract but can also offer OEM and ODM products.

Our products were adopted to various customers around the world in the equipment market of ACF connection process due to rapid growth of FPD industry.

Our tabletop COG bonder was an break-through product in the market, which was awarded by Nikkei Good Product of the Year of 1999.

We believe that COG process was only available for big factories, but our tabletop COG bonder gave a chance to small-sized workshops to get into the COG process.

And we successed in a development of the first "Fully automatic FOB line" 2006 in the world. By this development, we have had full line-up of ACF bonders including manual tabletop and semi-automatic bonder.

We launched touch panel laminator for the smartphone and tablet market in 2007.

We developed first LED Flip Chip "One-shot" Bonder for the future lighting in 2012, and contribute to a production of ecological devices.

We started to develop "System integration (FA equipment)" to take advantage of the knowledge and experience in 2013.

We have been developing the equipment related with the camera module for smart phone or mobile phone and the medical X-ray detector, and contributed greatly to customer’s production

Our business mission is "We become a leading company of the FPD and micro device market to develop and deliver the cutting edge products to work togethe with customers and partners". We offer the best products to meet the market demand continuously.

We wish you to give us the guidance and support.

Chairman Masayoshi Ohashi

WE CREATE THE MARKET WITH CUSTOMER AND PARTNER

TO OFFER NEW PRODUCTS,SERVICES,AND VALUE TO THE WORLD.

- We work together with customer to develop better products.

- We empower personal and group creativity and respond to market demand.

- We study science technology and offer attractive products continuously.

-

We all staffs participate in business management for company growth and

QOL improvement of company members.

- Company Name

- OHASHI ENGINEERING CO., LTD.

- Chairman

- Masayoshi Ohashi

- President

- Kazumichi Ohashi

- Founded

- August, 1959

- Location

- >Metal Division / Headquarters

>Tokyo office (* Head office function)

>Saitama Factory (System Engineering Division)

- Number of

- 90 employees (as of April 1, 2021)

- Business content

- System Engineering Division

・ ACF Bonder

・ System integrator (automation equipment)

Metal Division→HP

・ Precision sheet metal processing (OA equipment, FA equipment, medical / health / environmental equipment, amusement equipment)

・ Collaboration product with OHASHI CHISO LABORATORY (affiliated company)

① Mathematics art

② Beam robot

③ Various OEM / ODM products

- 1959

- Founded "OHASHI ENGINEERING CO., LTD." with sheet metal working business

- 1979

- Developed original equipment by improvement of sheet metal working business

- 1981

- New facilities of Headquaters

- 1984

- Second facilities (current Tokyo facilities) completed by business growth

Developed a prototype of Heat Bonder

Started system engineering business

- 1992

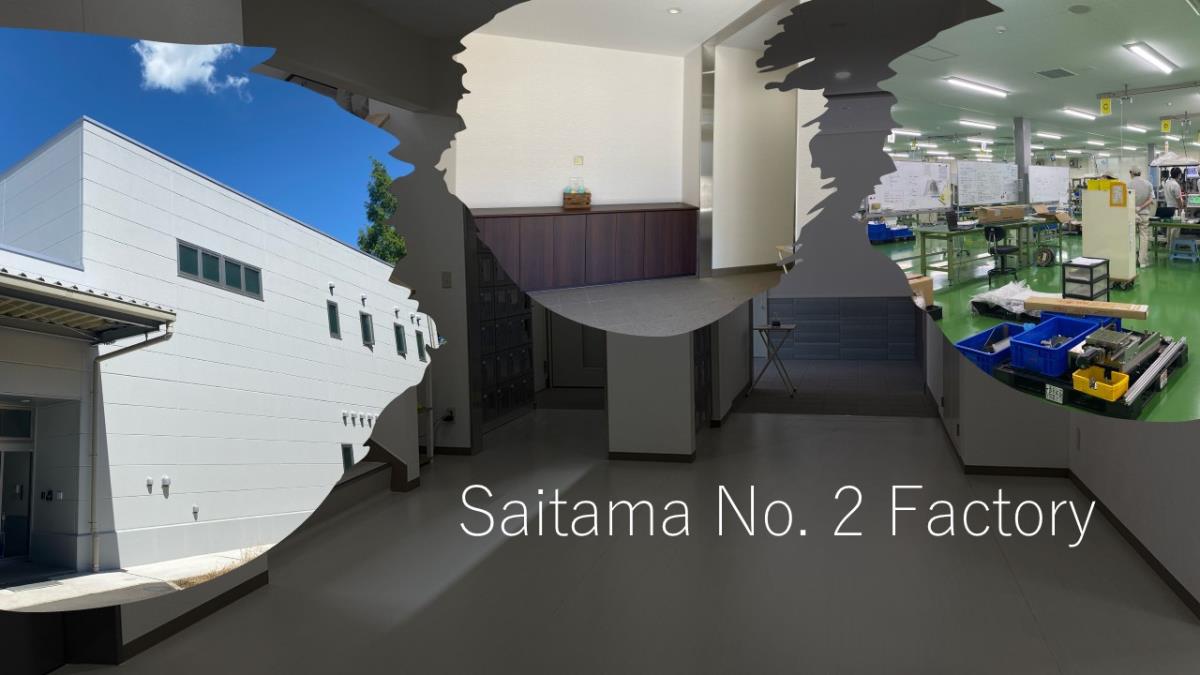

- Saitama Factory for OA, FA, and Amusement machine completed

- 1993

- Launched heat bonder (hiflex welder) in the market

- 1994

- Started ODA of OA, Amusement machine, and Environmental machine

- 1996

- Heat bonder business grown in LCD

- 1997

- Exported LCD module bonder in the world market

- 1999

- Tabletop COG bonder "Simple COG" was awarded by Nikkei Good Product of the Year of 1999

- 2001

- Approved ISO 9001 (System Engineering Division) & ISO 9002(Metal Business Division)

- 2003

- Updated ISO 9001 to ISO 9000 (2000 ver.)

- 2004

- Developed fully automatic FOG line and launched it in the market

- 2005

- Approved ISO 14001 (2004 ver.)

- 2006

- Launched first fully automatic FOB line in the world

- 2007

- Released Optical resin laminator in the market

Approved ISO 27001 (2006 ver.) (System Engineering Division)

- 2008

- Exported fully automatic FOB line in the world

- 2010

- Launched a development of LED Flip Chip Bonder

Launched "Sugaku Art" in the market

- 2012

- Developed LED Flip Chip Bonder "LMS Series"

Launched fully automatic ACF bonder for camera module.

- 2013

- Developed System integrator "Si series"

- 2014

- Launched fully automatic COF bonder.

- 2016

- Development and delivery of fully automatic FPC-equipped equipment

- 2017

- Development and delivery of fully automatic sensor module assembly equipment

Camera module fully automatic ACF Bonding System (high-speed, high-precision version) development and delivery

- 2018

- Direct Force Control Head Development

- 2020

- Saitama 2nd Factory completed

- 2021

- December 2021 Declined ISO27001 certification (self-activation)

Desktop COG mounting machine "Simple COG" won the Nihon Keizai Shimbun Annual Excellence Award

System integrator Si series development

Camera module fully automatic ACF Bonding System (high-speed, high-precision version) development and delivery

Saitama 2nd Factory completed

Quality policy

In order to achieve the business purpose, we will integrate the business operation management system and QMS, and effectively utilize QMS as a tool for promoting the management plan (action plan).

(Basic policy)

1. Analyze the internal and external situation surrounding the business division, clarify issues, and formulate a medium-term business strategy.

2. Break down the business strategy into an annual business plan (action plan) and set quality targets.

3. In order to achieve the quality goals, the annual plan sets implementation plans and goals (KPIs) for each department, reviews them regularly, and takes necessary corrective actions.

4. In the product realization process, comply with and improve the QMS rules and maintain their effectiveness.

5. Employees consciously work to differentiate products and improve their perfection in their daily work.

(Basic policy)

1. Analyze the internal and external situation surrounding the business division, clarify issues, and formulate a medium-term business strategy.

2. Break down the business strategy into an annual business plan (action plan) and set quality targets.

3. In order to achieve the quality goals, the annual plan sets implementation plans and goals (KPIs) for each department, reviews them regularly, and takes necessary corrective actions.

4. In the product realization process, comply with and improve the QMS rules and maintain their effectiveness.

5. Employees consciously work to differentiate products and improve their perfection in their daily work.

January 1, 2018

Representative Director Masayoshi Ohashi

Representative Director Masayoshi Ohashi

Environmental policy

In order to achieve the business purpose, we will integrate the business operation management system and EMS, promote the original business efficiently, and reduce the environmental load.

(Basic policy)

Appropriately recognize the environmental impact in all processes from sales to design / development, purchasing, manufacturing, delivery, installation and maintenance, and strive to prevent pollution and protect the environment including "9 global environmental problems

1. Establish and comply with voluntary standards based on related laws and regulations, other requirements agreed by the Company, and internal regulations.

2. Develop the identified significant environmental aspects into the annual environmental targets and implement continuous improvement.

3. Items that are relatively expensive due to corporate activities and whose improvement leads to a reduction in CO2 emissions will be treated in the same way as the significant environmental aspects and will be continuously improved.

4. Strive to improve the environment through transactions with suppliers such as partner companies.

(Basic policy)

Appropriately recognize the environmental impact in all processes from sales to design / development, purchasing, manufacturing, delivery, installation and maintenance, and strive to prevent pollution and protect the environment including "9 global environmental problems

1. Establish and comply with voluntary standards based on related laws and regulations, other requirements agreed by the Company, and internal regulations.

2. Develop the identified significant environmental aspects into the annual environmental targets and implement continuous improvement.

3. Items that are relatively expensive due to corporate activities and whose improvement leads to a reduction in CO2 emissions will be treated in the same way as the significant environmental aspects and will be continuously improved.

4. Strive to improve the environment through transactions with suppliers such as partner companies.

January 1, 2018

Representative Director Masayoshi Ohashi

Representative Director Masayoshi Ohashi

Scope of application

1. Design / development, manufacturing, installation and incidental services (maintenance / inspection) of electronics mounting equipment

2. Manufacture of precision sheet metal processed products (for OA equipment, FA equipment, medical / health / environmental equipment, amusement machines)

3. Design / development, manufacturing and incidental services (maintenance・Inspection) of material testing machines

2. Manufacture of precision sheet metal processed products (for OA equipment, FA equipment, medical / health / environmental equipment, amusement machines)

3. Design / development, manufacturing and incidental services (maintenance・Inspection) of material testing machines