PRODUCTS

We propose the automation system

We propose the automation system

that our customers want.

We propose from the automation of a part of the assembly process that relies on manpower to the automation of the entire line directly connected.

We consistently design, manufacture, and install in-house, and our experienced engineers provide accurate support from equipment startup to maintenance.

We will build strong cooperative relationships with material manufacturers, trading companies, and specialized manufacturers to technically back up our customers.

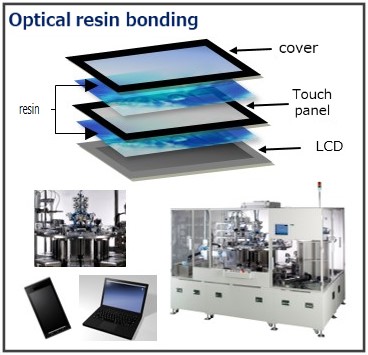

We are working on the development of automation equipment by utilizing the experience and knowledge we have cultivated in the display industry and the field of module parts assembly.

<Core technology>

Bonding technology, alignment image recognition, fine mechatronics, fine parts handling technology,

compact technology, resin coating technology

<Additional unit>

Laser marker, dispenser, laser solder, multi-axis robot, inspection measurement, special subunit

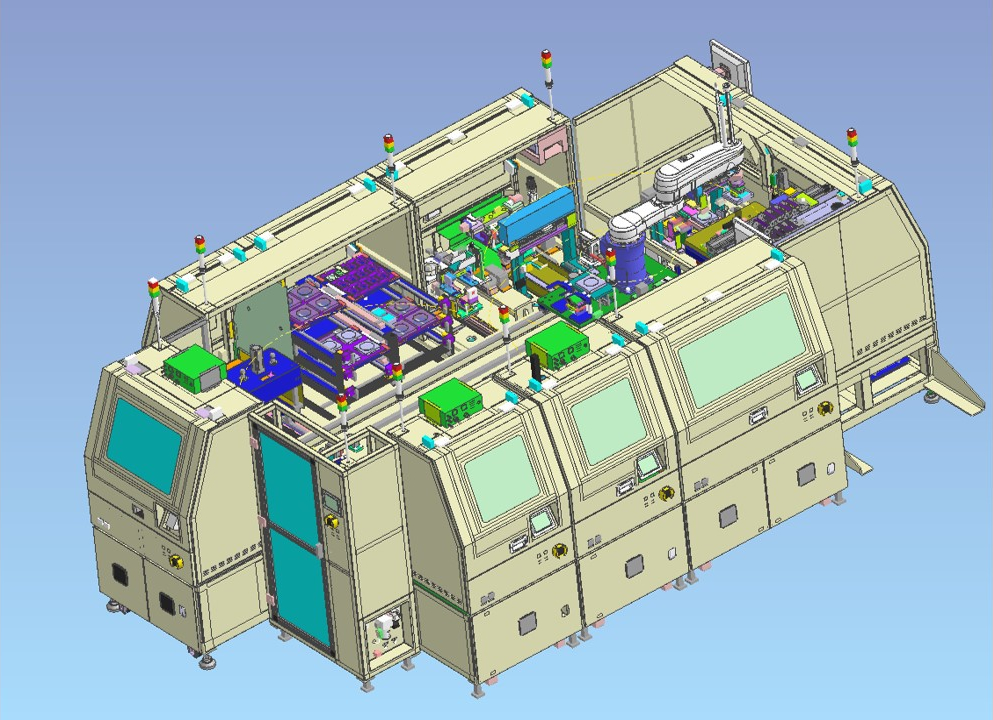

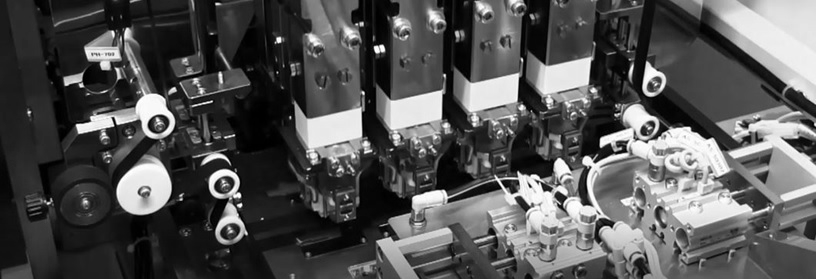

System example 1 :Electronic component assembly equipment

System example 1 :Electronic component assembly equipment

■ Machine overview ■

With the rotary table for the work taken out of the tray, transfer to each process

It performs resin coating, component mounting, resin curing, laser solder joining, and height inspection consistently.

■ Features ■

・ Equipped with dispense & UV lighting

・ Equipped with a laser solder unit

・ Corresponds to low loads of 30gf or less

・ Index stage transfer & cam mechanism

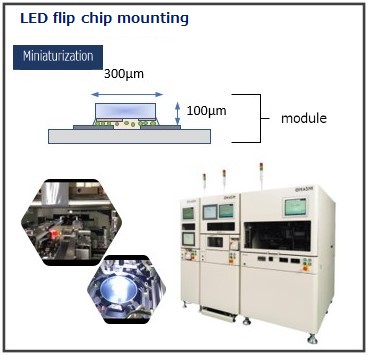

System example 2: LED lighting related cases

System example 2: LED lighting related cases

■ Machine overview ■

Fully automatic equipment that applies ACP to the pattern on the board, mounts LED bare chips, and performs thermocompression bonding

■ Features ■

Min. □ 0.3mm LED chip flip chip bonding

・ High load bonding up to 20,000N

・ High-speed mounting with multiple mounting heads

(9000cph)

System example 4: Laser marking equipment

System example 4: Laser marking equipment

■ Machine overview ■

A machine that manages printing and serialization on a variety of workpieces.

Printing on various workpieces such as FPC, IC, packages, and metal parts is possible.

Achieves traceability by directly connecting to the factory production control system.

■ Features ■

・ Marking possible to metal surface, FPC surface, glass surface, etc.

・ Marking position alignment function

・ Marking quality confirmation function